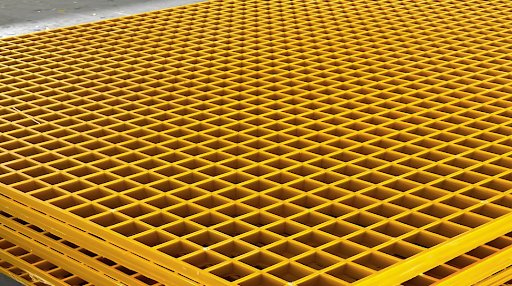

If you’ve ever walked through a factory, a wet market, or even a pedestrian bridge in Malaysia, there’s a good chance you’ve stepped on floor grating. At first glance, it might seem mundane. Just steel or aluminum bars forming a surface. But look closer. There’s more happening under your feet than most people realize. Floor grating solves problems. Big ones. Safety hazards, maintenance issues, drainage. And in Malaysia’s tropical climate, these problems get serious, fast. Floor grating in Malaysia is not just functional. It’s practical engineering tailored to the local environment.

Why Material Choices Matter More Than You Think

Steel and aluminum. Often treated like interchangeable options. In reality, they are very different. Steel grating is strong. Perfect for factories where forklifts and heavy machinery move constantly. Humid Malaysian air, though, speeds up corrosion. Galvanization helps, but it wears. Aluminium is lighter. Easier to install. Resistant to rust. Near the coast, aluminum often wins. Less upkeep, fewer headaches over the years.

Patterns matter too. Open mesh designs let water and debris pass. That prevents puddles. Which is crucial in wet areas. Closely spaced designs are used in hospitals or food processing plants. Hygiene and spill control matter more than drainage there. Choosing the wrong type creates long-term problems. Minor decisions now can save huge repair costs later.

Real-World Applications: Beyond Factories

Grating isn’t just for industry. You see it in bus terminals, wet markets, outdoor staircases, and flood-prone walkways. It manages rainwater efficiently. Supports heavy loads. Many businesses in Malaysia underestimate its importance. Until floors start rusting or warping.

Even small design tweaks matter. Anti-slip textures on aluminium grating reduce accidents. Wet areas benefit more than signs or mats ever could. Elevated platforms and catwalks use grating to combine visibility with ventilation. Workers can see below, airflow remains unrestricted. Small insights. But they make a huge difference.

Maintenance Insights That Often Get Overlooked

Maintenance may seem boring. But it’s where most installations fail. Steel grating needs inspection. Check for minor corrosion before it spreads. In Malaysia, mould and algae appear fast on damp surfaces. Aluminium requires less intervention. But regular cleaning is still wise. Especially in food or beverage facilities.

Installation shapes durability, too. Loosely anchored grating shifts under weight. Metal gets stressed. Lifespan shortens. Misalignment creates trip hazards. Or block drainage. Some local suppliers skip this step. Small mistakes become costly over time.

Design Opportunities Often Ignored

Designers sometimes hide grating as purely functional. But it can be aesthetic. Decorative patterns. Painted finishes. Strategic placement. Outdoors, in malls or rooftop walkways, it adds subtle visual appeal. Industrial zones benefit too. Patterned grates guide foot traffic. Highlight hazard areas. Visitors don’t consciously notice it. But the space feels safer, cleaner, and more organised. Small choices. Big impact.

Cost Versus Long-Term Value

Many focus on upfront costs. And that’s understandable. Steel grating is often cheaper at first glance. But Malaysia’s climate complicates things. Humidity and rain accelerate corrosion. Maintenance and labour costs pile up. Aluminium may cost more initially. But it resists rust. Requires less upkeep. Over the long term, it often proves cheaper. Planning for full lifecycle costs, not just sticker price, makes a huge difference. It prevents frequent replacements. Saves time. Reduces unexpected downtime.

Integration with Other Building Systems

Grating does not exist in isolation. It interacts with drainage, ventilation, and structural supports. Proper planning ensures systems work together. For instance, grating above drainage channels must matchthe flow capacity. Otherwise, flooding can occur. Elevated platforms need to consider airflow, lighting, and visibility. Poor coordination turns a strong grating into a weak point. In Malaysia, with heavy rain and high humidity, integration is not optional. It is critical. Safety and performance depend on it.

Conclusion

Looking down at floor grating in Malaysia, it may look like just metal bars. But it’s much more than that. A silent problem solver. Balancing strength, drainage, safety, and design. Material choice, pattern, and installation—they all matter. Get them right. The floor lasts decades. Reduces maintenance. Keeps people safe. Designers, engineers, and business owners who pay attention see the difference. Grating becomes not just functional. But smart, integrated, and even visually thoughtful. As Malaysia grows in construction and industry, floor grating quietly remains one of the most practical innovations shaping everyday spaces.